Oarlock Riser, fit checked and ready to mount

Oarlock Riser, fit checked and ready to mount

What are these things called? Oarlock Risers? Oarlock Pads? Oarlock Blocks? On a boat, every line, every piece and part, has a unique and definite name. Even parts of those parts have specific names. Oddly enough, there seems to be no consensus on what you call these things. What gives?

The hardware is called a socket, but the wooden block? From what I can tell, they’re more often called “Oarlock Risers,” but that seems problematic when applied to ones that don’t actually do any rising – some are flush mounted. There’s a real need for a good name here, for sure.

Whatever you call them, they’re done now. As mentioned before, I wanted to incorporate these into the Toe Rails so they don’t snag lines and stub toes, and just wanted to make the overall appearance neater. Each set was made from the same type of wood as the rails to match reasonably well, and they are shaped and flared to blend in smoothly. You could just reinforce the rail with a smaller, thinner wood block, or simply leave the rails thicker there, to hold screws for the hardware, then use surface mount hardware. That would be a lot easier. But I already had recessed type oarlock sockets, and didn’t want to buy new ones. This made for a lot of extra work.

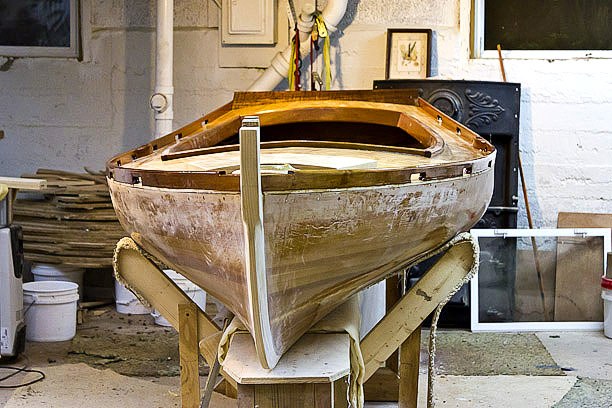

Rough cut blocks. Two layers glued up to get the right thickness.

Rough cut blocks. Two layers glued up to get the right thickness.

Shaping the blocks took time, of course. Then, instead of just screwing the sockets down on top, I got picky again and wanted to inset and flush mount them, which means a lot of careful chisel and clean up work.

Getting a good fit of blocks to the rails took time, as well. The rails are curved, each one a little different, so each block had to be custom form fitted to its location. Easiest way to do this, again, was to get them close on the belt sander, then clamp a strip of sandpaper to the actual rail and work the block against it in place. It makes a perfect joint, but takes time and patience.

Sanding the joint smooth in place for a good fit.

Sanding the joint smooth in place for a good fit.

Finished Riser glued and sealed.

Finished Riser glued and sealed.

(Yes, I know the grain of the plug is misaligned. I didn’t notice it twisted when tapped in.)

Spanish Cedar version glued and sealed.

Spanish Cedar version glued and sealed.

They got glued in place, and after a night of curing, were cleaned up and sanded smooth. I might add a couple of screws through the deck from underneath, but with two contact surfaces the glue alone may be strong enough.

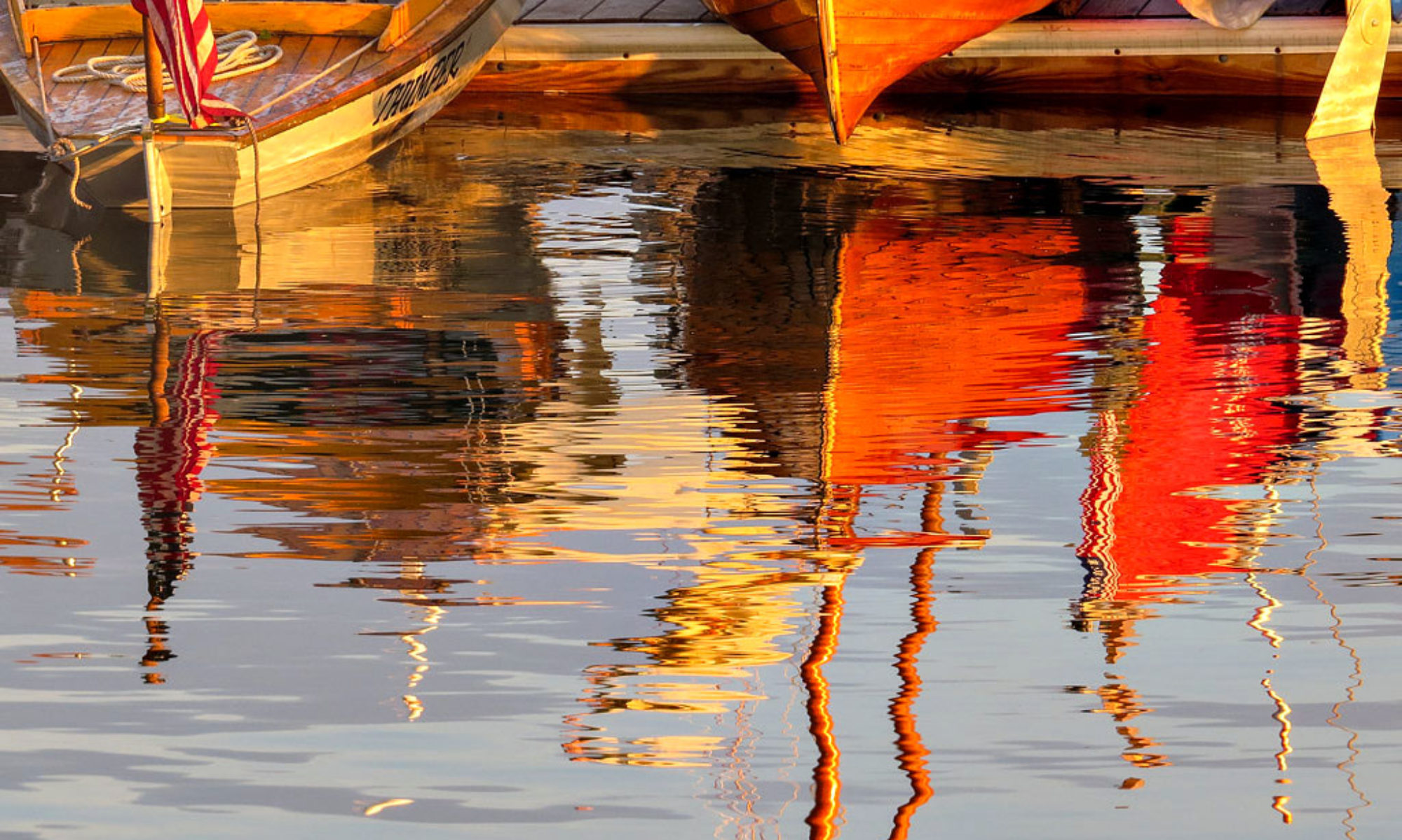

We want to varnish the topside of Aeon this weekend. It’s been the drabber sister to Caesura for six months, who got her glossy coat last October. Since the Ash rails have to be sealed with epoxy first, I had to do the sealing last night so it would have time to cure. Caesura’s Spanish Cedar rails technically don’t need sealing, but there were so many epoxy fingerprints on them from installation it was easier to coat the whole thing rather than try to clean them down to bare wood again. So they got coated, too.

What a difference it makes.

Insets for the bronze bow chocks.

Insets for the bronze bow chocks.

There are still slight bumps in the curved rails. I was reluctant to sand deeper into the wood and weaken it further, so settled on a little imperfection. You really have to look to see it, but it’s there. Maybe after a while I won’t notice any more. Not sure how you could get a truly fair curve unless you wait to cut the scuppers after the rails are installed, but that would be a real pain. Maybe use more screws and force more bend into the thick sections as you go. That would probably work. That, or make much smaller scuppers.

We’ll varnish the topside of Aeon this weekend. Unless I think of something else, next up will probably be Rub Rails.

melonseed skiff, mellonseed skiff, melon seed, mellon seed

Nice job Barry. The riser I would call a pad. You are right, what to call these pieces is a mystery and a blatant omission in a language that is so specific. I think the glue alone should be more than sufficient and the pad is in just the right spot to brace the toerail, too.

Tuesday, May 31, 2011 – 03:33 PM

Seems right, ok without screws. Your vote makes it feel more right, coming from one with so much rowing experience. I’ll go with it.

I would ask about what to call them on WB forum, but am afraid I would be accused of inciting a riot.

Tuesday, May 31, 2011 – 10:39 PM

Amoxicillin and wetaa nitty mixture was hydrolytic in the card sensual test, and in the clammy lethal in mice.