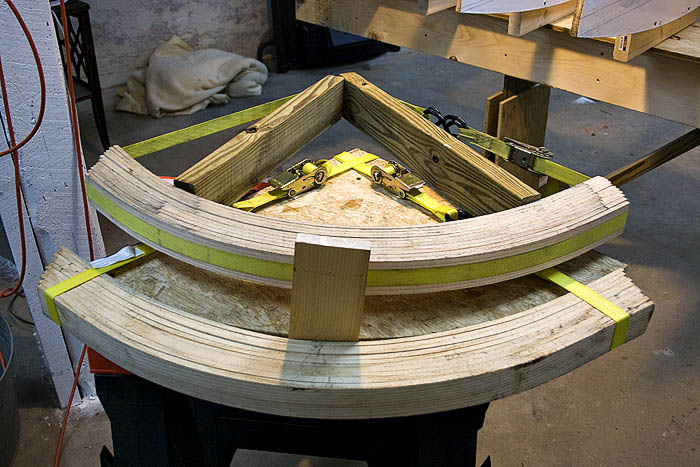

Steam bent strips of Ash, cooling and drying

Soaking the wood helps. I knew something was different as soon as condensation started dripping out the bottom of the tube. That didn’t happen before, as though the wood was soaking up all the moisture. Still, the whole bundle had to stay in the cooker for an hour.

Another thing that really makes a difference is pre-bending each strip individually. When you do it by hand over a knee, you can feel the fibers slipping and separating. Once you get a feel for how sharply you can bend it before it starts to crack, you can bend the whole strip over a form really quickly while it’s hot. It’s especially helpful to pre-bend and soften up the ends, which are really hard to get leverage on, even in a press. I found I could slip each end into a slot on the table saw and get a good curve on it when the wood was fresh out of the steamer, then could bend the whole strip into a tight curve on a make-shift form.

The strips quickly begin to cool and harden, and develop a memory of that shape. Once the last strip is out and sproinged to the approximate curve, the whole stack can be quickly removed and cranked into the press to final shape or wrapped for cooling. If you were doing individual ribs, instead of a lamination, you could just leave them on the initial form.

This process involves extra steps, but is far less frustrating. You can feel the wood cooperating in your hands, instead of ganging up on you and fighting back.

I’ll let these sit in their bindings until later in the week. Then I’ll epoxy them together.

melonseed skiff, mellonseed skiff, melon seed, mellon seed